Asil Celik announces investments aimed at broadening SBQ manufacturing capabilities

Asil Celik is the largest special steel producer in Turkey, servicing the automotive, machine manufacture industries, amongst others, both in country and around the world. Around 75% of Asil Celik’s 550.000-ton capacity is directly or indirectly exported, mainly to other industrialized nations.

Over the years, Asil Celik has developed a large and prestigious client base. To name a few examples; Renault, Fiat/Tofas, Karsan, Otosan, Turk Tractor, Hidromek, Ford (light commercial vehicle and truck division) and Mercedes (Bus and truck division) in Turkey. BMW, Mercedes, VW, Audi, Scania, Volvo, CAT and John Deere, around the world. Asil Celik produces custom made, critical application special steel for all these companies and more.

In addition to existing product range, Asil Celik has started investments in the production of high-quality steels, stainless and tool steels.

Phase 1. Investment for the production of stainless steels

- Decarburization unit,

- Enviromental investments

Phase 2. Tertiary metallurgical process investments, with the addition of:

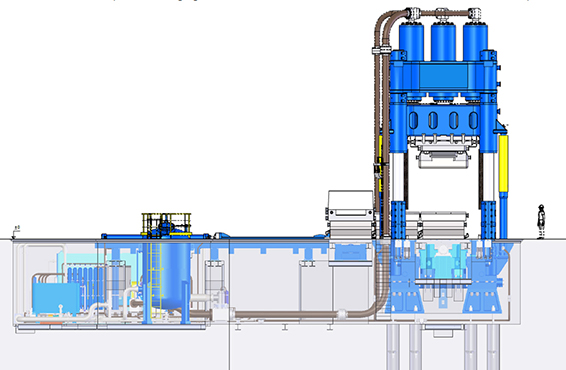

- Electro slag re-melting (ESR) facility,

- Vacuum argon re-melting facility,

|

| Electro slag re-melting (ESR) facility |

Phase 3. 60.000 ton/year forging facility, consisting of:

- Forging press,

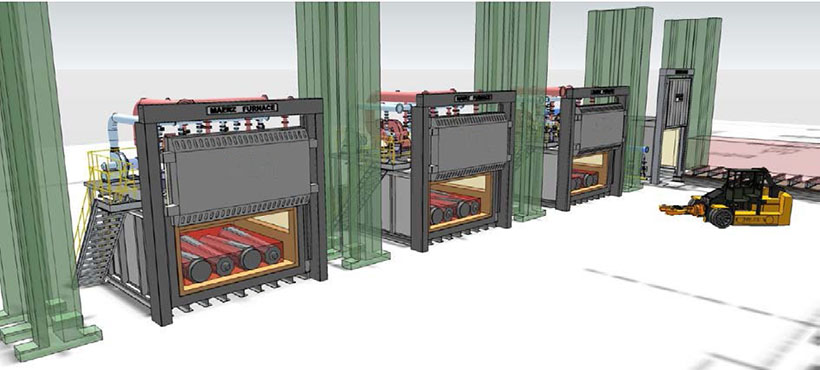

- Annealing furnaces,

- Quench and temper and other heat treatment furnaces,

- Inspection and finishing lines,

- Grinding and peeling facilities,

|

|

| Forging press | Forging press |

Once the investment is completed, Asil Celik will have the capacity to produce 100 to 500mm Round, square and rectangular forged or rolled billets, as well as some other products, not currently produced in Turkey. These will include:

- Stainless steels,

- Tool steels,

- High strength thick or thin walled seamless pipe,

- Up to 500 mm diameter forged (round and square) bars and axles,

- Railroad axles,

- Marine shafts.

|

|

| Annealing Furnaces | Heat Treatment Facilities |