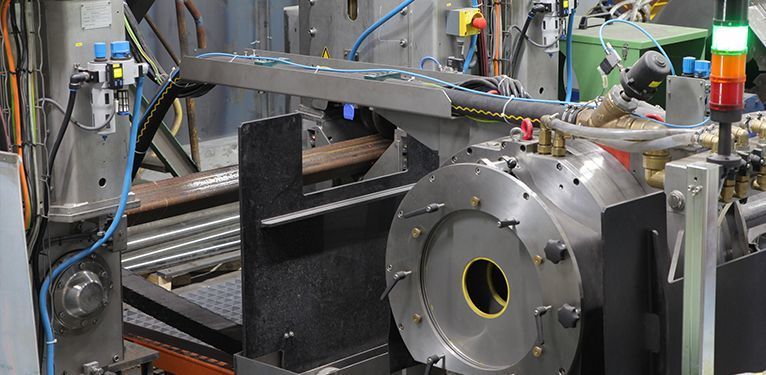

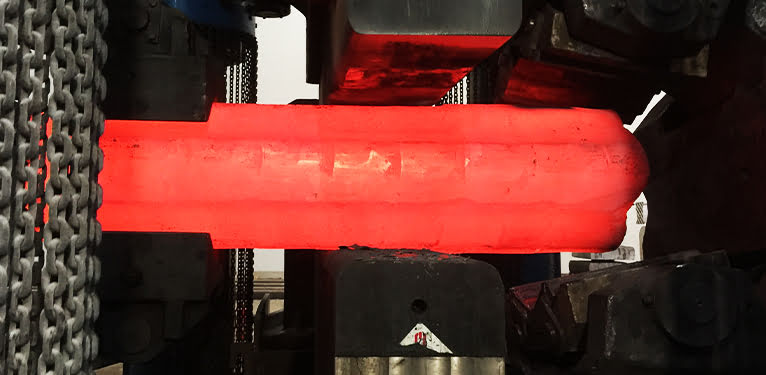

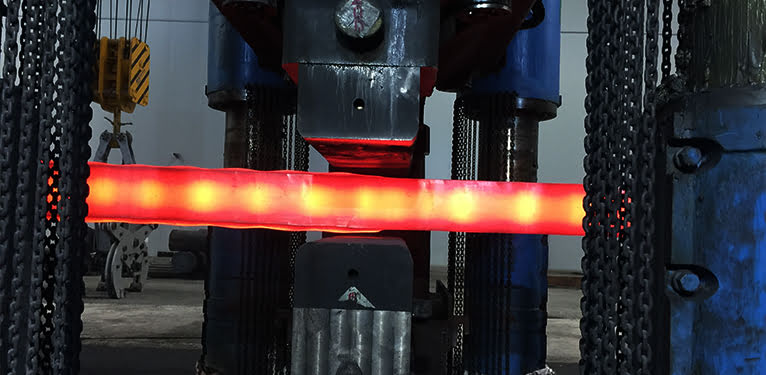

400 different quality of steel are produced in our facilities under alloyed, non-alloyed and high alloy production categories. This number could increase to 1200 based on various customer specifications. In addition, production versatility is also increased based on sections and customer demand.

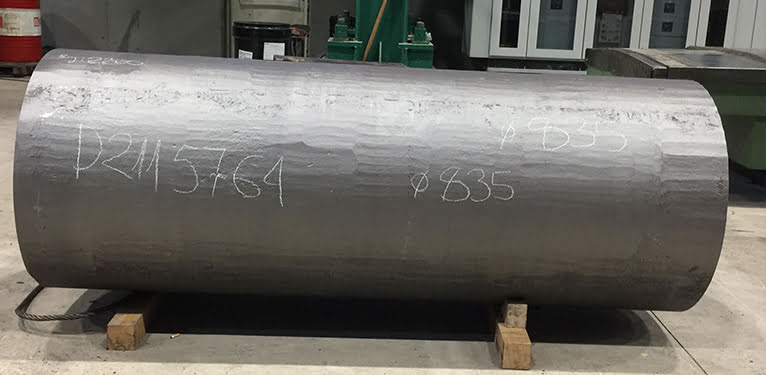

Our products are used mainly in Automotive Industry, Spring Manufacturing Industry, Nuts and Bolts Industry, Energy Sector, Machinery Production Industry, Seamless Pipeline Industry and Pressured Tube Industry.